The brick sewers of NYC date back to the mid 1800’s and many people actually consider them things of beauty. Unfortunately they pose structural issues and issues of functionality as well. Even so brick NYC sewers continued to be built long after superior sewer line materials such as vitrified clay pipe came into existence. To this very day many property owners have issues with house sewers connected to NYC sewers made out of brick.

Two of the many issues concerning brick sewer lines

- The mortar used

Mortar of questionable quality was sometimes used that wore out and left a brick-on-brick condition – The mere weight of the bricks on top of each-other is frequently all that is left holding the sewer together. In some instances water penetration and outside ground pressure actually can cause a brick city sewer to collapse.In addition mortar was sometimes placed in sub-freezing weather further compromising the integrity of the final product.

Frequently a house connection has a flow of water against the inside course of bricks. This causes the area of the city sewer around the connection to become porous and the connection to settle or the bricks to cave in. In certain cases the soil outside the city washes into the city sewer causing maintenance problems, stoppages, and roadway wash-outs.

- The flow of waste water

Because courses of brick do not provide a smooth surface, sediment will accumulate and also cause a restriction to water flow. This is not an issue with other material such as cast iron, vitrified clay, and concrete poured into forms – all of which all have a smooth surface.

Some more facts about public sewers made from brick

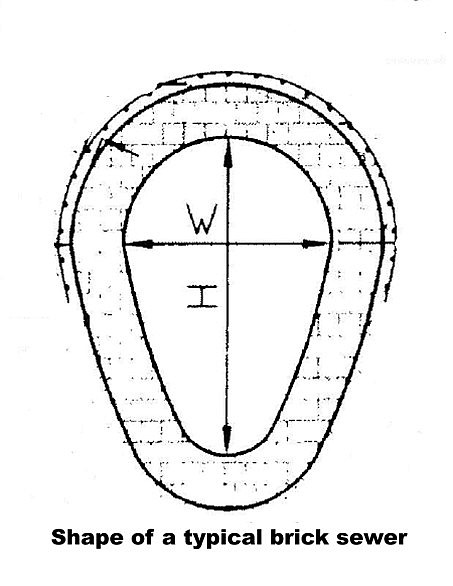

Obviously there is tremendous weight placed on any underground utility. However more than any other type of approved material brick is susceptible to failure unless properly designed. That is why brick sewers are oval or egg shaped. In that way the weight is dispersed and there is less stress on the structure.

Can a brick sewer be rehabilitated?

Recent restoration of brick sewers in the New York area and in other parts of the country have shown that brick sewers as small as 30″ can be successfully lined with shotcrete. Larger diameter sewers are easier to work in. However experienced and specialized contractors can produce acceptable results by employing skilled staff and proper materials in a wide range of sewer sizes. Using shotcrete is a way of essentially relining the inside of the sewer which prevents deterioration of the system and makes the sewer water proof.

What can happen when new connections are added

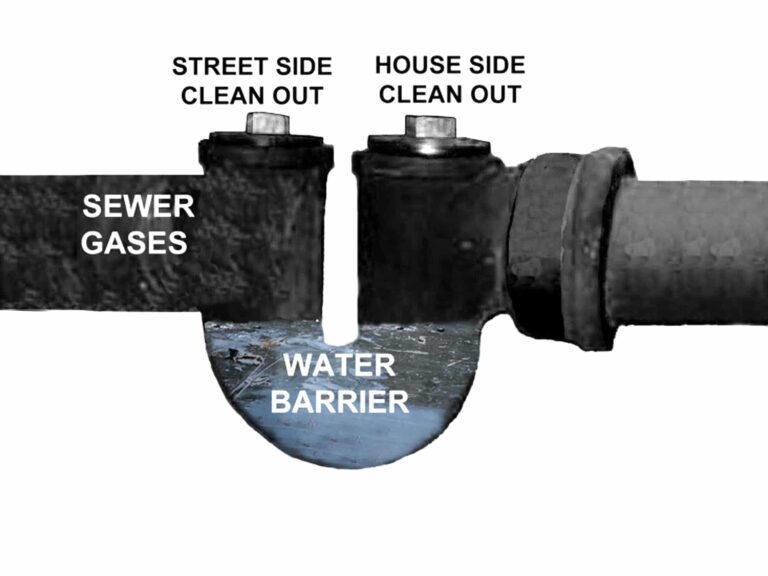

Since brick sewers were primarily built in the 1800’s the development of NYC was essentially in its infancy. Because of that fact the water flow inside the sewer was relatively low, which posed no problem for house sewer line connections made just above the flow line. The problem that arose was that as NYC was developed with many new buildings erected the water level inside the sewer got increasingly higher. Many buildings built earlier were left with their connection to the public sewer literally being under water – under the flow of the waste water in the city sewer. Of course this creates continuous maintenance and sewer back-up issues.

House connection work must be done with great skill

Because of the issues with brick sewers, house sewer work must be performed with great skill and expertise. Special care must be taken to ensure that new connections and replacements of existing New York City house sewers function properly and are also long-lasting installations.

Sewer replacement work – As stated above many times the present connection for a house sewer will be under the flow line of the inside of the public sewer. In cases like this the existing connection should not be re-used. The correct course of action is to plug the existing connection and make a new drill-in connection at a higher elevation that is above the flow line.

Making a new connection to a brick sewer – There are four steps to properly make a new connection, referred to as a ‘drill in’ connection.

- Choose a point of the city sewer that is above the flow line and provides proper pitch for the house sewer to function properly.

- Place approved wire reinforcing mesh on the outside of the bricks for added support and strength.

- Encase at least a 2′ x 2′ section of wire mesh with an approved concrete mix which will provide needed support and strength to properly hold a new connection without damaging the public sewer.

- Lastly after the concrete has cured properly a core drilling machine is used to core through the concrete, wire mesh, and brick sewer in one action. Typically a diamond core drill bit one size larger then the connection size is used.

As with any excavation work approved backfill material must be utilized and proper compaction in one foot lifts. Poor backfill practices are sure to ruin even the most professional subsurface installation. But maybe more importantly is that when working on any NYC sewer or house sewer line connection highly experienced individuals should be employed. Being familiar with all the various types of city sewers and and house sewer line materials is vitally important. Most important are company-wide commitment to safe work practices. High quality subsurface plumbing installations and job-site safety are a great duo.

About Balkan Sewer And Water Main Service

Since 1952 more New Yorkers have trusted Balkan to install and repair their water line and sewer services than any other plumbing company. Our expertise is unmatched and our commitment to service and quality are unwavering.