There are various common Causes of a broken sewer line, and there are appropriate solutions as well. A sewer line is an important part of every house, yet it is probably the least maintained part. This is not because homeowners are lazy, but because sewer line maintenance procedures involve professionals. When the problems are misdiagnosed due to lack of experiences or adequate tools, the results can result in unnecessary repairs which can cost thousands of dollars.

Some problems can be resolved with only simple tools, such as a plunger, or flushing the sewer line with strong chemical substances. While other problems, such as a broken sewer line, must involve invasive excavation and replacement. Understanding the exact cause of a sewer line problem leads to effective repair, so you can save money. There are at least six common problems in a typical residential sewer line, as briefly outlined below.

1. Broken Sewer Line Due To Pipe Settlement

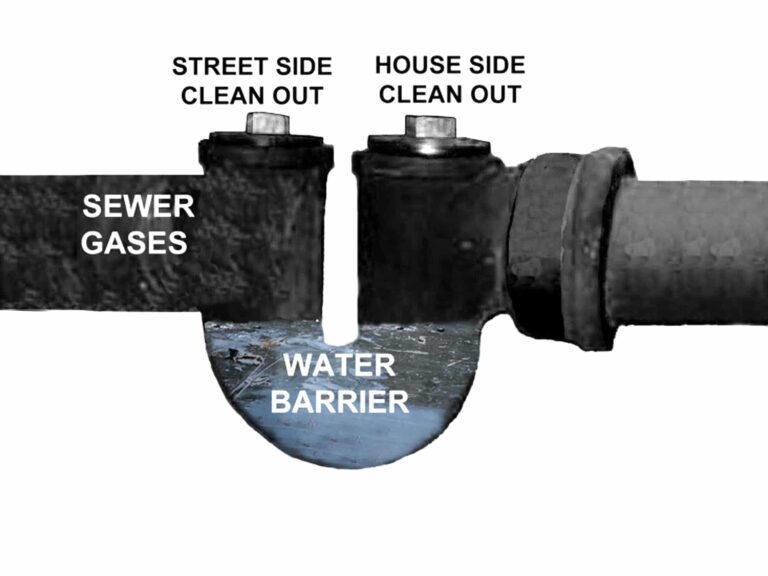

One of the most common problems is back-pitch, which is frequently caused by settlement of the pipe in an area. When the dirt under or around the pipe has settled, the pipe will sink and create negative slope. Waste and water that should go downhill will stop in the sunken area. Over time dirt, grease, and waste, will accumulate in the settled pipe causing a blockage or even back pitched sewer.

• Solution: the only possible solution is to replace the sunken pipe. Sunken or settled pipe is probably bent or cracked, too. The problem can be corrected by making an excavation to replace the damaged line. This is a job best left to a professional sewer contractor because it is essential to find the exact location of the settlement and dig the right area.

2. Improper Sewer Line Installation

Many problems can arise from improper installation. If the sewer installation was handled by a professional and done to code, a broken sewer line caused by “low area” should be unlikely. But unlikely does not mean unheard of. Under normal conditions, sewers are installed with 1/4-inch slope per foot. In difficult areas where pitch is critical, a city inspector may allow 1/8-inch slope, but this is not recommended. Under each joint or hub of a sewer pipe, a brick or other suitable object should have been used to prevent settlement. Frequently crushed stone is placed underneath the entire run of pipe to accomplish the same.

A sewer line works based on the simple principal of gravity: the water runs downhill. There is nothing complicated or mechanical about it. Improper installation, however, can lead to back-pitched problems. Besides poor installation, negative slope is possibly triggered by shifting soil. Severe low areas will hold water and all the debris it brings. If not treated immediately, the pipe can crack, collapse, or cause ever more frequent backups due to grease build up.

• Solution: The only way to fix improper installation is, unfortunately, excavate the improperly installed area and have the pipes reinstalled. In most cases, this is a costly repair and it requires accurate diagnosis about negative slope locations.

3. Sewer Pipe Root Infiltration

Roots can get inside a sewer line, and will get inside when there is crack in the pipe. It happens mostly with clay pipe because of its weak vitrified connection. Cast iron pipe is much less susceptible to root infiltration. When roots do get inside a pipe, they will continue to live and eventually outgrow the width and strength of sewer pipe. Roots often grow in multiple spots, so it requires complete inspections throughout the pipe length.

• Solution: If the symptoms are recognized quickly, you may only have partial blockage problem. In this case, chemical treatment using copper sulfite or similar compounds will help to kill the roots, avoiding more expensive repair. Treatments with chemicals need at least partial flow of water because you flush the chemicals into the sewer line. If the roots have completely blocked the pipe, the only resort is replacement. As mentioned earlier, roots usually grow in multiple spots, so replacing one spot is useless effort.

4. Sewer Pipe Deterioration

Frequent treatments with chemical substances and continuous exposure to water will inevitably cause corrosion. Metal pipes are strong, but they deteriorate over time. Underground environment in most, and moisture helps to quicken deterioration process. Pipe thickness is worn away all the time by water; thin pipes are easily cracked causing sewer line to break.

• Solution: There are at least two workarounds to fix severely deteriorated pipes: lining and bursting. Pipe lining is the process of installing new pipes inside the old ones. The new pipes can be applied to a small area or the entire length depending on the old pipe’s condition. Pipe bursting is a similar process, but instead of installing new pipe inside the old one, this method break apart the old pipes and replace them with the new ones.

5. Pipe Breaking or Cracking

All small problems like rust, settlement, and root infiltration can lead to broken sewer line. But if the broken pipe is merely triggered by tear and wear, the repair is easier.

• Solution: Unlike tree roots problems which can spread across the pipe, broken sewer line often happens in a particular spot, and therefore the repairs are made in that area only or commonly referred to as “spot repair”. It still involves excavating and replacing, but it is easier once the cracking spots are located.

6. Damages by external causes

Deterioration, grease, fats, and corrosion are common problems and everyone should expect to pay maintenance costs to tackle those issues. However, there are external causes such as excavation for tree planting, excavation for underground utility installation or repair, and other external causes as well. When the soil is excavated for any reason including for planting trees, the excavator may hit an existing sewer line.

• Solution: It is difficult to tell how deep a particular sewer line is, and accidents do happen. Please put in mind that if the line has ideal 1/4-inch slope per feet, this type of problem can be fixed with a spot repair. In addition the contractor at fault usually will repair the broken sewer line at no charge. If not, it is advised to carefully document the damage, repair it at your expense, then file a claim.

THE DIFFERENT TYPES OF SEWER PIPE

• Clay pipe: This is one of oldest types used for sewer line construction, being used for many hundreds of years. Clay pipe is baked in a kiln (vitrified), hard to cut, and resistant to chemical degradation. A major downside is that it has joints that become porous over time, leading to tree root problems.

• Cast iron pipe: The material is strong and non-flammable. Similar to all metal materials, cast iron can rust and corrode, but over a very long period of time. Caste iron joints are quite water tight, and resistant to root growth. However cast iron is susceptible to damage from acidic or alkaline water.

• PVC and ABS: There are plastic pipes with smooth surfaces both outside and inside, making water flow smoothly through them. The biggest advantage is that PVC does not rust, has great waste-water carrying capacity, and is very low cost. However, it is not as strong as their cast iron counterpart, and more prone to breaking or deflecting.