When it comes to operating a brass gate valve, or a gate valve of another material on a main water line, observing a few simple rules can help you avoid a plumbing repair and aggravation. Opening a valve or closing a water valve properly will surely prevent damage and unnecessary repair work.

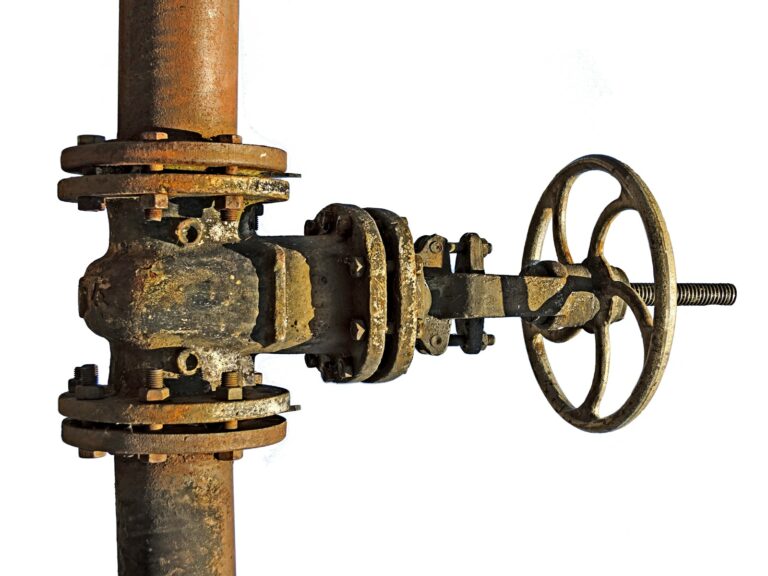

Additionally, operating a main control valve properly will add years of service life to the valve, and prevent unnecessary valve repairs. A brass gate valve is one of three types of water valves used on water service lines. The other two types of water valves are a full port opening ball valve and an OS&Y valve.

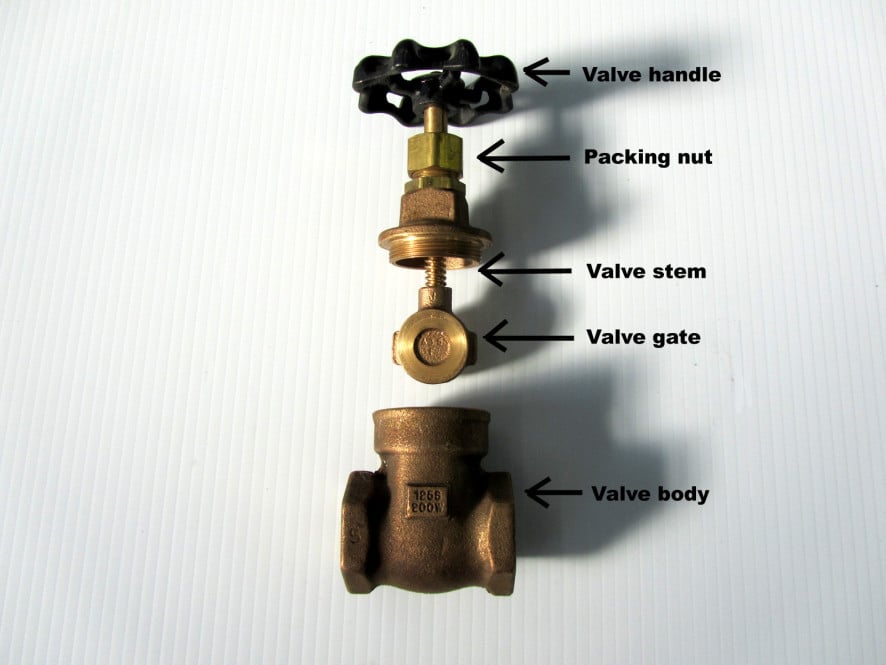

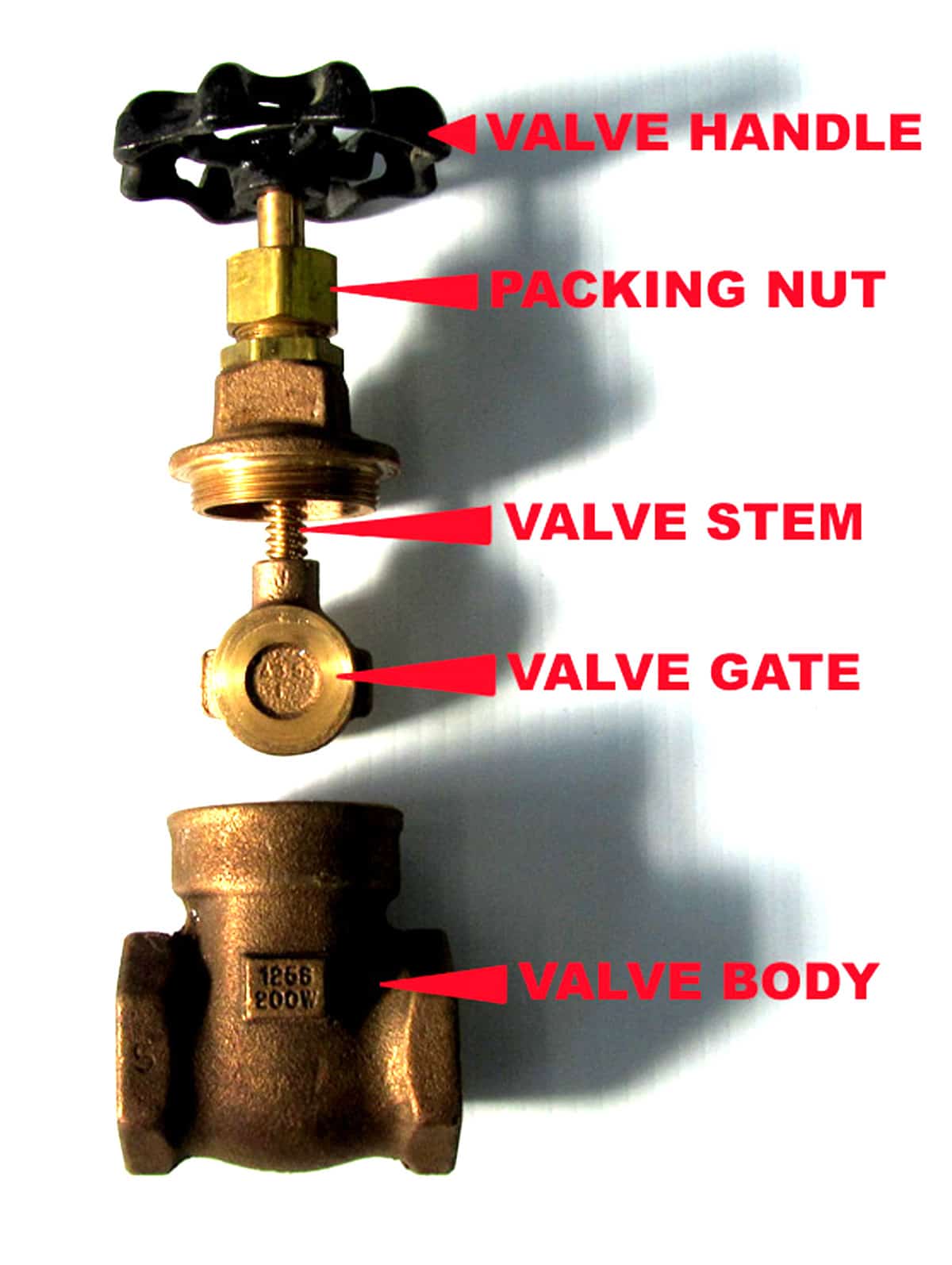

The components of a brass gate valve

A brass gate valve, or any gate valve for that matter has some very basic components. If you plan on opening or closing a gate valve, it’s important to understand how these valve components work to avoid damage or a loss of water service. There are 2 major valve components to understand to avoid getting yourself into trouble:

1. The Valve Stem

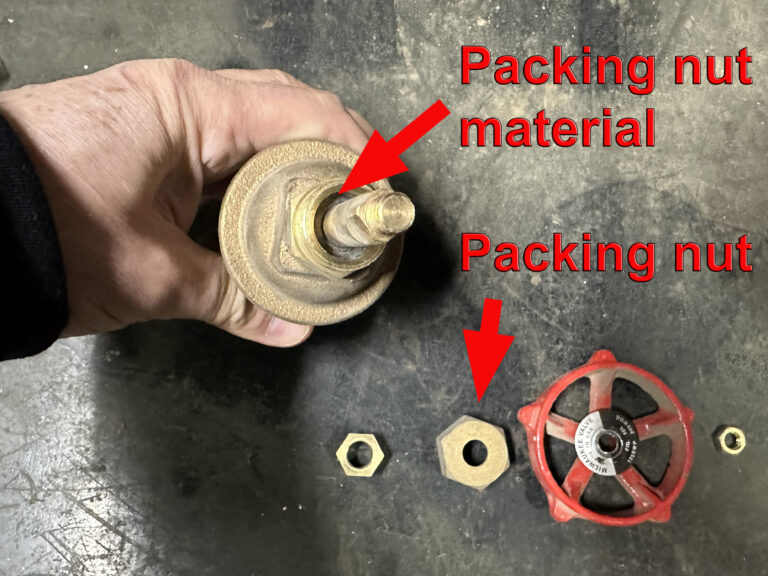

A brass valve stem is what connects the valve handle to the gate inside the valve body. This allows the gate to rise or lower. Never use brute force to open or close a valve. That can cause the stem to break in either the open or closed position. If the valve handle will not turn, just loosen the packing nut a bit.

2. The Valve Body and Valve Gate

Be aware that debris, sediment, or corrosion can accumulate inside the valve body. This can prevent the gate from sitting properly inside the valve body and allowing the valve to close 100%.

As stated above, never apply force to try to fully close the valve. Simply open a nearby sink, remove the sink strainer, and work the gate valve handle back and forth. This will allow the sediment or debris to break loose, and then flow out from your sink. In many if not most cases, this simple trick will allow your water valve to fully close.

How to open a gate valve on a main water line

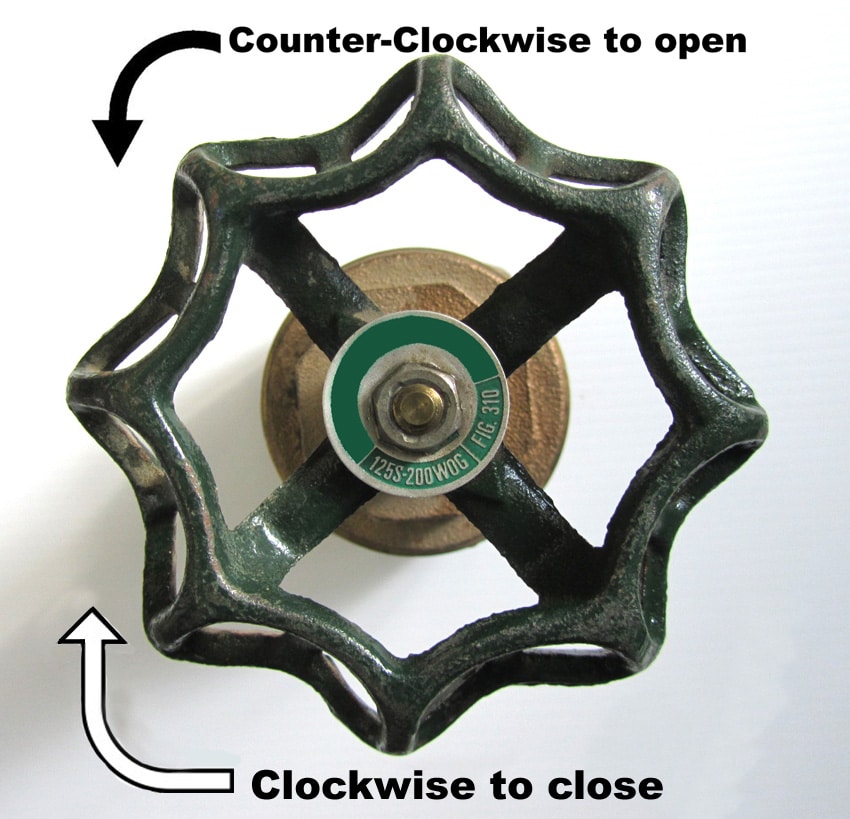

The proper way to open a gate valve is to gently turn the handle counter-clockwise (to the left) without applying excessive force – do not ‘jerk’ the handle.

A typical 1″ main control valve for a water line will take about six full turns to fully open. Stop turning as soon as there is any resistance.

Turning the handle or stem too far with excessive pressure can cause damage and very often will cause a leak.

Helpful Tip #1

If you meet resistance when trying to open a main control valve, if it is a gate valve loosen the packing nut one turn. The packing nut is on top of the gate valve body. That will allow the stem to move more easily. Always remember to tighten the packing nut after you are finished opening or closing the water to prevent a leak.

Helpful Tip #2

If there is no water in the plumbing system when opening the valve, always open a faucet on the top floor of the building to let air escape from the plumbing system. Air that is left in the plumbing can cause water hammer and this can blow apart your piping causing considerable damage.

How to close a gate valve on a main water line

Applying excessive pressure to a gate valve to make it close “all the way” has the effect of bending the gate, its seat, or seal and doing permanent damage.

Sometimes excessive pressure or jerking the handle will cause the stem to snap. Excessive pressure can cause the valve to break in the closed position and cut off the water supply to the property.

Helpful tip: If a gate will not fully stop the flow of water, never apply excessive force. Frequently debris or sediment may accumulate inside the body of the gate valve preventing the gate from fully closing.

There is a method to get sediment or debris out of a valve body. With a faucet open inside the building gently work the handle open and closed to flush out the sediment of debris. In most cases, this will allow the gate to fully close. Never try to force the gate to close by using excessive pressure or force, this is the primary cause of the valve stem snapping in half.

If the water flow still will not completely stop call a licensed master plumber. Most skilled plumbers can perform a valve repair of a valve replacement at a relatively modest cost. Never risk damage to your property by trying to perform work you are not capable of or knowledgeable about.