Pipe electrolysis often happens when stray direct current (DC) electricity causes the pipe to decompose. However, copper pipe electrolysis and corrosion in home piping systems can also potentially be caused by many modern appliances. Modern appliances tend to rely on solid-state electronic systems, and can therefore be related to electrolysis in copper pipes.

As an example of how electrolysis occurs, even a small hairdryer can create a tremendous amount of DC current. This direct current can then be sent through the grounding wire on a water service line, and distributed randomly underground. Copper corrosion in home piping can also be caused by this same stray electric current.

Because copper is an excellent conductor of electricity, it will attract any of the stray DC (direct electrical current) in the vicinity. Thankfully, the vast majority of current flowing underground is alternating current (AC) electricity. Unlike DC current, AC current does not negatively affect copper water lines.

Connecting dissimilar metals also causes electrolysis

Dissimilar metals that touch can also create this problem. That is why it is important to keep other unlike metals, such as galvanized pipe, from coming in contact with your copper pipes. Something as simple as a discarded nail in the soil, or in your home’s ductwork, can trigger electrolysis if they happen to touch your copper pipes.

Copper pipe electrolysis also occurs with galvanized pipe, this is also known as galvanic action. This occurs when the two dissimilar metals are connected directly to each other.

So, how will you know if your copper pipes are suffering from copper pipe electrolysis? Your copper pipe will turn green and start to show pitting. It does not take long for damage from copper pipe electrolysis to appear either. Within just a year, your newly installed pipes may start leaking.

Where are stray electrical currents most commonly found?

Stray currents are most frequently encountered on water pipes in the general vicinity of electric railway tracks. A second common location is near cathodic protection systems typically used to protect gas mains. However, stray electrical currents can occur virtually wherever metal water pipes coexist with an electrical system.

What areas are prone to water line electrolysis?

Historically copper pipe electrolysis has been a problem in certain areas of the city because of the DC electricity used by the MTA subway system. Leaking currents from the trains make their way through the soil to nearby pipes. The alternating current (AC) used in homes and businesses does not pose the same threat to pipes.

In some documented cases, damaged underground utility lines will also cause pipe electrolysis. In the case study below, a water main contractor created a condition of pipe electrolysis by performing a faulty installation.

However, electrolysis attacking water lines is now appearing throughout the metropolitan area of NYC. Recent studies seem to indicate that solid-state appliances may be creating a rash of water lines destroyed by electrolysis in multiple neighborhoods. But regardless of the true cause, the dramatic increase in resulting water line breaks is indisputable.

A case of underground copper pipe electrolysis in Brooklyn

Pipe electrolysis can sometimes be a self-created issue, as a recent job in Brooklyn proved. The existing water service for this property had been replaced less than three years ago. Yet this relatively new copper water line was a victim of pipe electrolysis, which caused the copper water line to leak prematurely.

Unfortunately for the property owner, the previous water main contractor did not perform the work to code, and damaged underground electrical utility lines during their installation. Once a water line leak occurs, it’s important to know how to report a water main break and what action to take.

Instead of carefully exposing underground utility lines, or installing the copper main at an appropriate depth, the line was installed 2′ deep. It was then forced through the electric ducts. By doing this, the protective transits for the ducts were damaged, and electricity was allowed to flow into the ground. Since the copper line was nearby, the electricity began to flow through the copper water main.

Needless to say, K copper water tubing is not made to carry live electric current. Hence, in less than three years, the line was leaking and severely pitted from pipe electrolysis.

The new installation performed by Balkan Sewer And Water Main Service was done over 2′ deeper than the previous installation and at a depth over 4′ deep. Which was well below the electric lines, and beyond the reach of any stray current. This particular Brooklyn water main replacement became a primer on the importance of choosing the correct water main contractor to perform an installation. As an added peace of mind, the client received an unconditional ten-year guarantee.

Two primary solutions to prevent copper pipe electrolysis

There are two primary solutions for preventing stray electric currents from destroying your water service line.

- The first method is by using dielectric couplings, but this is technically not permitted in many areas (NYC included).

- Another effective method is by completely encasing the copper water line in PVC plastic (or another appropriate plastic tubing) and using approved tape to wrap the areas of the copper tubing that cannot be installed inside the plastic.

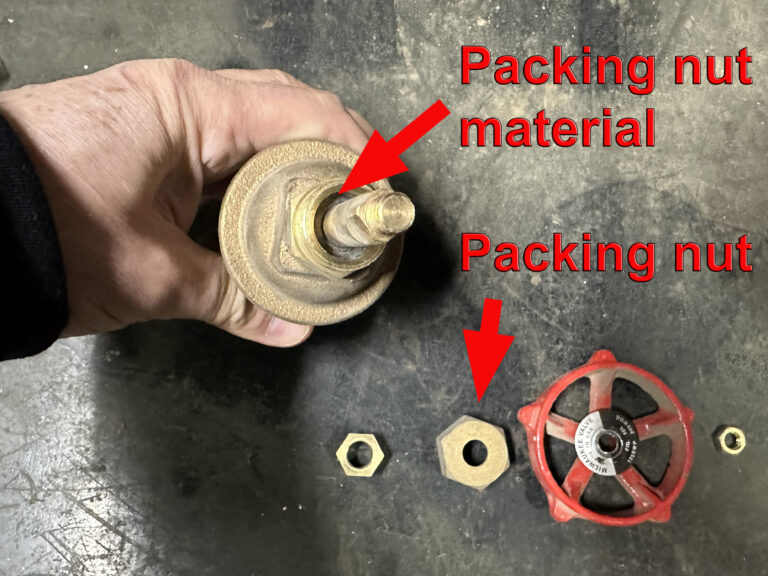

Dielectric couplings break the flow of electricity

Installing dielectric unions at the connecting points on your water supply line should provide the necessary break in continuity to protect them. However, dielectric unions, once installed, prevent your water service line from acting as a ground for your electric service. In NYC it is expressly required by electric code that your water service line act as a secondary ground. Therefore dielectric couplings are not technically legal in NYC.

It should be noted that the American Water Works Association (AWWA) issued a policy over 20 years ago recommending that metal water service lines be isolated from metallic mains (such as gas mains).

The AWWA also advised against the often required practice of grounding electrical utility service lines to water service lines inside buildings. Regardless, in most cases, a 2nd precaution must be taken during the water service line installation. The 2nd option described below is the preferred option.

Install copper water lines through a plastic sleeve such as PVC

The more preferred option is typically done by installing the copper tubing inside of a larger diameter plastic tubing. Similar to copper electric wiring, it will insulate the K copper. Instead of protecting you from electric shock, it protects the copper from exposure to electric current. This must be a task trusted to a skilled and licensed professional.

If even one small piece of copper is exposed, it will accelerate your water line’s demise. If only a tiny bit of copper is exposed, the stray direct electric current will all concentrate on that little bit of copper. Copper pipe electrolysis and the failure of your water line can occur in just a couple of months.

Choose Your Water Main Contractor Carefully

If you live in one of these vulnerable areas, you must choose a Licensed Plumbing Contractor who understands copper pipe electrolysis: its causes, prevention, and treatment. It is most important that any plumbing contractor takes the proper and documented steps to prevent pipe electrolysis from reoccurring.

It’s important to note that damage from pipe electrolysis is typically excluded from any guarantee, so hiring a trustworthy and knowledgeable professional is vitally important.

Working on water pipes exposed to stray electrical currents also presents a danger to workers. Unless precautions are taken, workers can be exposed to electrical shocks, which is yet another reason to hire none but experienced and licensed plumbers.

If you suspect that your copper pipes are suffering from copper pipe electrolysis, contact Balkan Sewer And Water Main Service. We guarantee that your problem gets fixed and stays fixed.