A jackhammer is an amazingly helpful tool for many construction applications. If you’re going into the construction field or have a job to do, chances are you should learn how to use a jackhammer. Some major points of consideration are safe job site setup, proper personal protection equipment (PPE), and understanding the tool itself.

As a side note, before the advent of air compressors and pneumatic jackhammers, construction work took on a whole different nature. Roadways were broken out using a pick and a pointed bar, rocks were broken out of holes by alternating making a fire on top of the rock, and then dousing it with cold water. Before the use of jackhammers became commonplace, the good old days of construction were in fact the hard old days of construction.

Proper Site Safety Set-Up Before Using A Jackhammer

Similar to basically any construction task, the very 1st important step is to ensure a safe job site setup. Learning how to use a jackhammer, means learning how to work safely and protect others as well. Most times a jackhammer will be used in a public space, be it a sidewalk area or a roadway. Some of the major points of having a safe job site are:

- Set up a work perimeter that prevents the public from entering your work zone.

- Place appropriate signs that inform pedestrians and vehicles that a work zone exists.

- In some cases, arrow signs may be needed to direct traffic of pedestrians to alter their route.

- As using a jackhammer can cause flying debris, always cover any articles that could be damaged. Knowing how to use a jackhammer therefore also includes protecting surrounding work areas.

- In very sensitive areas you may want to use water to keep the dust down or sawcut the area to be broken out first.

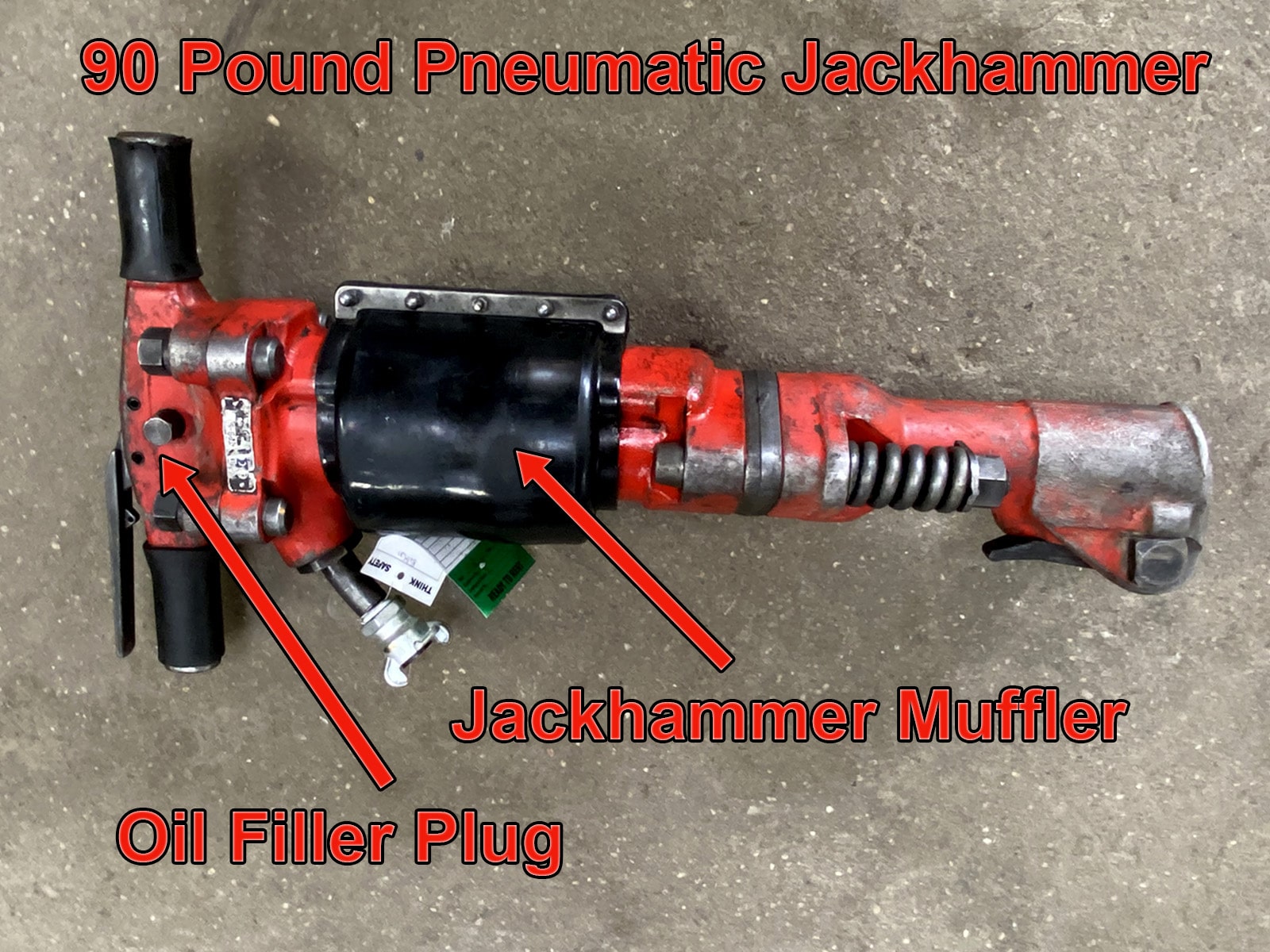

- Always make sure that your jackhammer has a muffler attached to it. The protects your hearing, as well as the general public. In most areas, a jackhammer muffler is required by local law and codes.

Always Wear Proper PPE (Personal Protection Equipment)

Personal protection equipment (PPE) must be used before operating a jackhammer. Protecting your own safety is a vital component of knowing how to operate a jackhammer. The following PPE items are vital and “must haves”. The cost of PPE is always a small fraction of the cost and potential devastation of an injury.

- An OSHA-approved hard hat.

- Work gloves are highly recommended to protect against blisters and pinching. You might strongly consider anti-vibration work gloves. Jackhammer use transfers vibration from the tool to your hands and the joints of your fingers. Anti-vibration work gloves are not expensive, and they greatly relieve the stress on your hands and fingers.

- Safety goggles that are vented (so they do not fog up on you).

- A reflective vest is always a good idea, even if you’re not in a roadway.

- Steel-tipped work boots.

- Metatarsal guards are a must. Either purchase metatarsal guards that can be laced into your existing work boots or purchase work boots with the guards built in. This little-known piece of PPE will save you from a broken foot if your jackhammer slips or moves in an unexpected way and lands on your foot. As a side note, metatarsal guards are mandatory for all field works at Balkan Sewer & Water Main Service.

- An N95-rated dust mask that is vented for when you exhale. Non-vented dust masks allow for dust to enter the mask when you exhale.

- Ear protection is vitally important to protect against the high decibel level of a jackhammer. Approved ear protection comes typically in 2 styles, either ear plugs or headphones. As both work perfectly fine, it’s really a question of your own preference.

When Using A Jackhammer, Do You Need A Helper?

The short and sure answer is yes. Working alone with a heavy and tricky tool such as a jackhammer is foolhardy. Typically one person runs the jackhammer, and another person removes the broken debris and operates the air compressor. If challenges arise, such as heavy lifting, a 2nd worker is mandatory. Therefore, another key part of knowing how to use a jackhammer is having an assistant present. This is particularly true when using a jackhammer below the surface for work such as a water main repair or a sewer line repair.

***IMPORTANT SAFETY NOTE ABOUT HOW TO USE A JACKHAMMER SAFELY: Never operate a jackhammer while your helper is standing or reaching into the direct area of the jackhammer. Never lose sight of the fact that a jackhammer is capable of causing catastrophic injuries.

Which Style & Weight Jackhammer Do You Use?

Understanding your task at hand allows you to understand which style and weight of jackhammer you’ll need. While an electric jackhammer is lighter and does not require an air compressor, it is far less effective than a pneumatic jackhammer. For most “true” construction jobs such as sidewalk or roadway demolition, the desired jackhammer is a 90-pound pneumatic jackhammer.

No matter the jackhammer you choose to use, you must take the time to understand it and learn how to use it. Knowing which type of jackhammer is appropriate for the takes at hand is a key part of how to use a jackhammer.

***NOTE: Jackhammers require lubrication to work properly to avoid them from getting damaged. A small container of approved oil mix should be on hand. The mix can be inserted directly into the jackhammer, there is an oil reservoir with an easy-to-remove plug built into the jackhammer. If you’re in a rush, the oil can be poured directly into the air hose line once you release all of the air pressure.

Safely Connect Air Hoses Before Using A Jackhammer

If you’re using a pneumatic jackhammer, you must use air hoses of course. Because air hoses are subject to being twisted, turned, and exposed to traffic, special care must be used when connecting them to each other and to a jackhammer. Once a pressurized air hose breaks loose it can cause injury and property damage. Typical air hose connectors must have whip checks installed to prevent them from flailing wildly if they disconnect while pressurized. There are specialty connectors that prevent air hoses from disconnecting. These are pictured below.

***IMPORTANT SAFETY NOTE: Never take apart air hoses unless you have completely released all pressurized air inside the houses. Turn off the air valve at the compressor, and turn on the jackhammer until all of the air is released. Taking apart pressurized air compressor hoses can result in injury.

Using A Jackhammer Requires The Proper Bits

Knowing how to use a jackhammer requires understanding the two basic styles of bits that are used. Since there are two basic surfaces that jackhammers are used to break, concrete and asphalt, there are likewise two different bits utilized. There is also a 3rd type of bit known in the trade as a “combo bit”, but I do not recommend it.

- An asphalt bit for a jackhammer is about 5” wide. As asphalt is a softer material than concrete, the force of the jackhammer can be spread across the 5″ width of the bit and still break through the asphalt. This bit also allows for asphalt to be broken into manageable sections, as opposed to little pieces.

- How to use a jackhammer on concrete requires a concrete bit, or point is the 2nd required bit. A concrete bit is specifically designed to break up concrete. As concrete is a very hard material, all the force from the jackhammer must be concentrated to the point of a bit in order to be effective.

- Knowing how to use a jackhammer on rock will depend on the type of rock you’ve encountered. In some cases, it may be a soft rock that can be broken by using the pointed jackhammer bit used for concrete. However, in most cases, specialty tools such as a hydraulic rock splitter will be needed.

***NOTE: Always have 2 of each of the above bits. If one gets stuck, you’ll need to 2nd bit to break it out.

Other Required Tools

- Sharp digging bar.

- Round point shovel.

- Square shovel.

- Wire snips (in case concrete has reinforcing wire).

- Commercial grade broom.

How To Use A Jackhammer: The Proper Grip

A key to knowing how to use a jackhammer, like many tools, is to let the tool do the work. Unlike what you may think, using a light grip on the jackhammer handles is preferred. A light grip lessens the vibration that works its way back to your hands and throughout your body. You should use a grip that is just hard enough t control the jackhammer itself. It doesn’t work any harder or faster the tighter you grip it!

How To Use A Jackhammer: Proper Angle & Pressure

Possibly “the” biggest key on how to use a jackhammer is to let the jackhammer do the work. There is no need to push down hard on the jackhammer when using it. Just use a light enough pressure to give the tool proper direction. The weight of a 90-pound jackhammer is enough to break both asphalt and concrete.

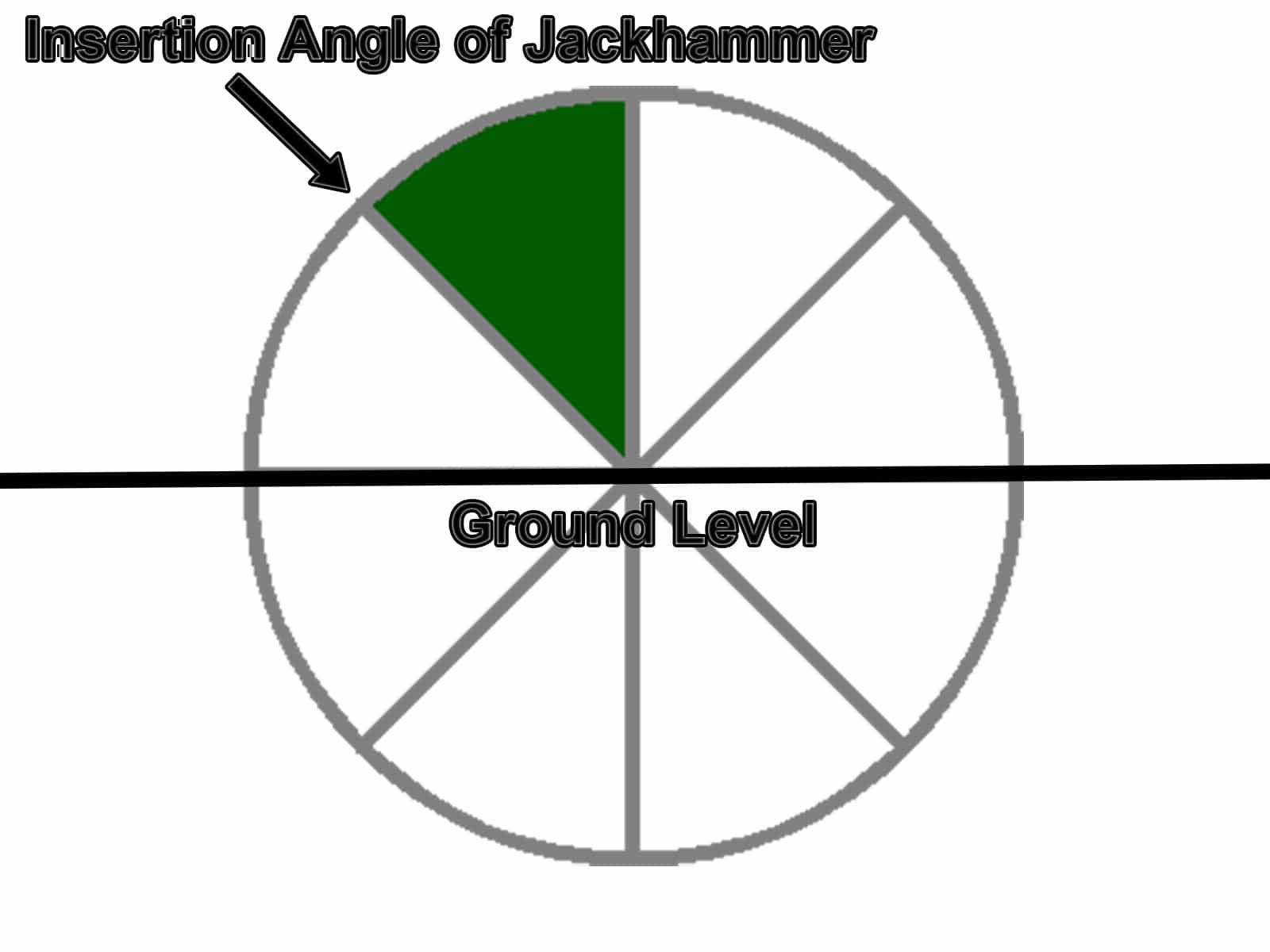

Knowing the proper angle for this tool is another big key to knowing how to use a jackhammer properly. Unlike what you may think, never insert the jackhammer straight in, or on a 90-degree angle. Inserting a jackhammer straight in, or straight down, then means you have to lift the full weight of that same jackhammer back up again for each and every insertion.

Jackhammers should be inserted on about a 22-1/2 degree angle, the equivalent of about 1/8 of a circle. That allows you to use the leverage of the surface and your lower leg to lessen the burden when repeatedly lifting the jackhammer from each insertion. If the jackhammer hits a sticking point, the angle of insertion also allows for more easily extracting the jackhammer.

What To Do When Your Jackhammer Gets Stuck?

It is common for a jackhammer to get stuck in concrete or asphalt when making a penetration. Typically rocking the jackhammer itself side to side, or up and down, will release the bit. In some cases, you can remove the jackhammer from the bit, and then tap the bit side to side using a mallet. Never strike the top of the bit, that will ruin the smooth finish and can damage the jackhammer itself. If none of the above works, that’s where having a 2nd backup bit is important. You would remove the jackhammer from the stuck bit, insert the 2nd bit, and break out the bit that is stuck.

*** IMPORTANT SAFETY REMINDER:Never let hands, fingers, or feet get involved in the process of trying to remove a jackhammer bit that is struck. Never lose sight of the fact that safety is job # 1 in knowing how to use a jackhammer.

The Team Balkan Series Of Safety Articles & Videos

Team Balkan is devoted and passionate about safety. This article is another in a series of in-house safety initiatives that we felt would be helpful to the general public. Unfortunately, the most energized and well-meaning worker can sometimes be the least informed about safe work practices. That naturally includes DIY’ers, and homeowners as well. Never let the excitement and determination to complete a task be the cause of an injury.

About Balkan Sewer And Water Main Service

The Balkan Team provides expert sewer and water main repairs and replacements. We are experts in all types of NYC underground plumbing. Balkan Sewer And Water Main Service was founded in 1952. Since its inception, the foundation of the company has been based upon integrity and honesty in all of our dealings. That solid foundation has enabled us to thrive in every economic climate.

The year 2022 actually marked our 70th consecutive year in business. As we have grown, we have become increasingly dependent upon a “Team First” approach.

A Team First Approach Ensures High Standards

What helps ensure a continuation of our high standards, overall integrity, and high company morale, is that same team approach. Complete client satisfaction has always been the number one goal at Balkan Sewer And Water Main. That is why we are NYC’s largest and most trusted sewer and water main service in New York City. Simply put, if it’s plumbing, and it’s underground, we do it. For over 70 years, and for over 90,000 New Yorkers to date, Balkan is “The Team You Trust”.