There are a variety of water main valves, and each are made with different purposes in mind. They are manufactured in different styles, and a variety of sizes. Water main valves that are installed using the incorrect style or size can be a code violation, pose a fire hazard, or result in a decrease in the supply of water to a building.

The following tutorial explains each type of valve clearly and it’s primary purpose. Trust an experienced NYC water main contractor to use high quality water main valves for their correct application that meet or exceed code requirements.

Water main valves used inside a building

Gate Valves

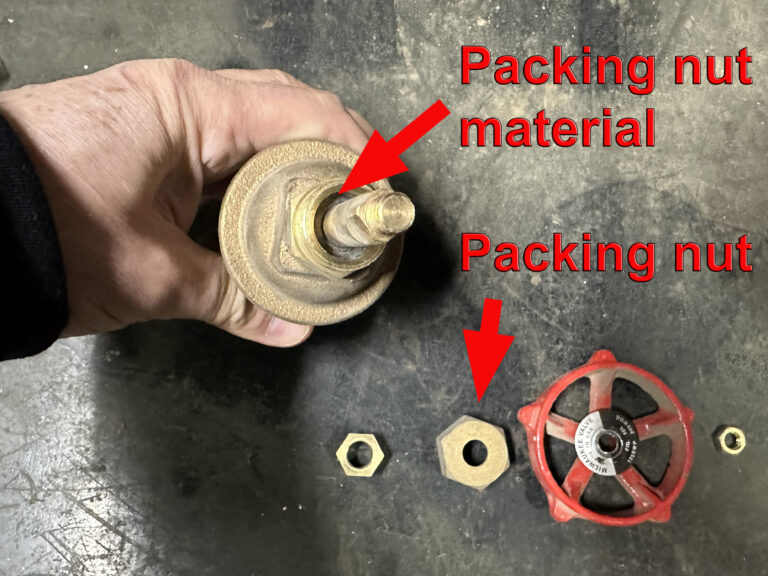

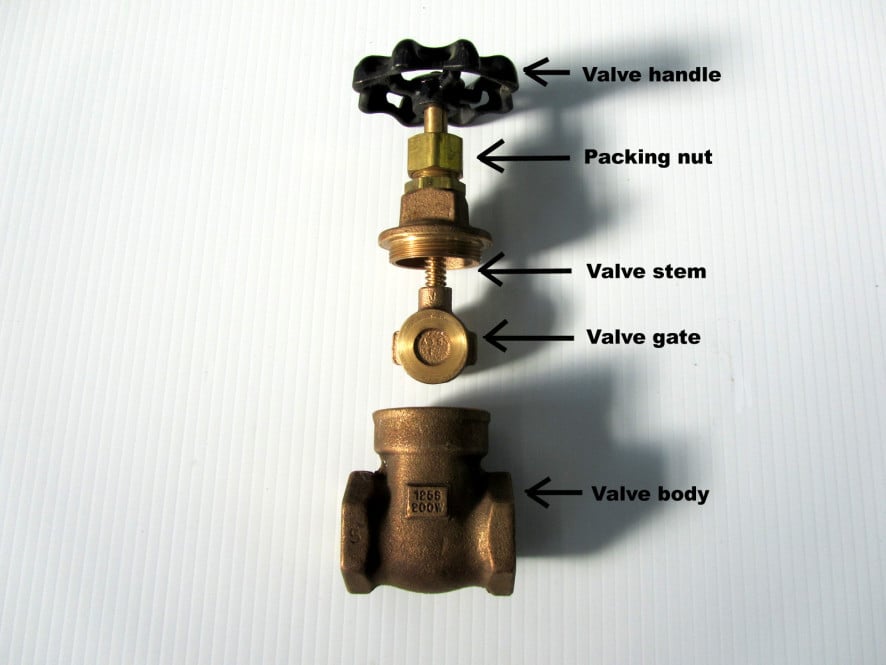

Gate type valves operate by raising and lowering a gate inside the valve body when the stem of the valve is turned by a handle.

Turning clockwise closes the valve, turning counter-clockwise opens the valve. The gate seats inside the valve body to make a water tight seal.

Ball Valves

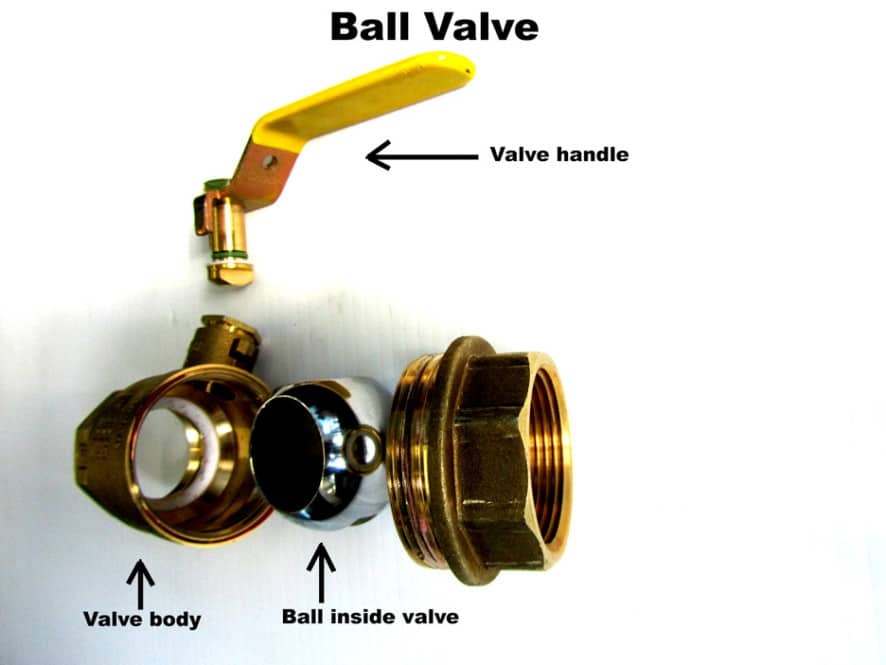

Ball type valves are legal for domestic water supply in NYC, but they must be full port opening (the opening water flows through must be the full size indicated on the valve body).

Ball valves are fully closed or opened by a 1/4 turn of the valve handle.

OS&Y Valves

OS&Y valves are used for water service lines that involve fire protection. OS&Y stands for outside screw and yoke.

That means that unlike a normal gate valve, you can always tell when an OS&Y valve is open or closed – this is vital for proper fire protection.

Water main valves for street connections

Wet Taps

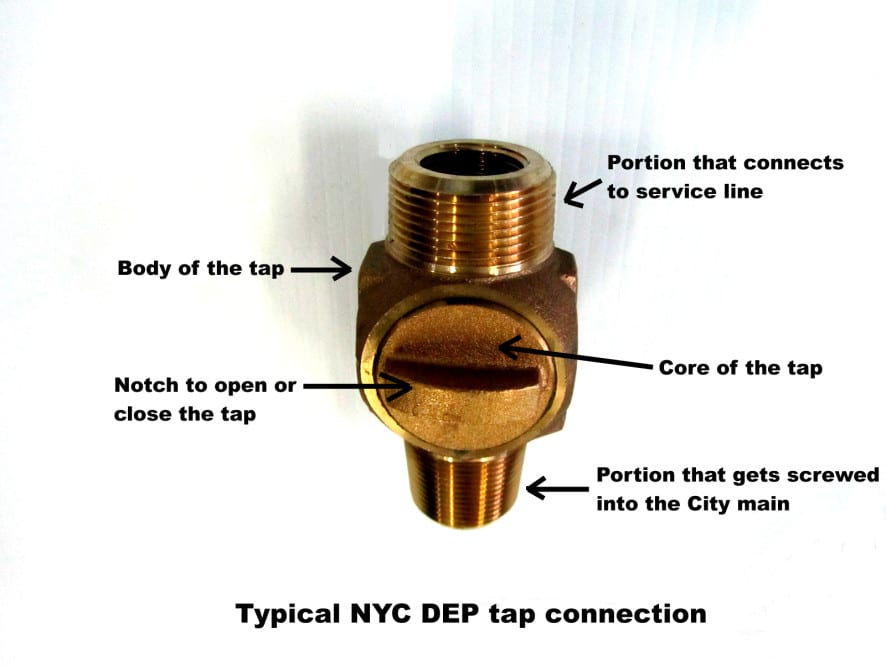

A wet tap connection is used for connection size requirements up to 2″. In NYC dedicated DEP tapping crews expertly install these water main valve connections in about 20 minutes. Only about 2 quarts of water is lost in the installation process.

A tap is installed by drilling a hole into the city main. A proper size tap connection is vital to obtain proper water pressure and volume for a building.

Wet Connections

A wet connection is used for water service line sizes 3″ or larger. They are typically required for multi-family buildings or when a building is fully fire sprinklered. It is also installed by special DEP field personnel but takes longer to install than a tap.

To install a wet connection a hole is core-drilled out of the City main the same size as the connection size.

Sidewalk curb valves

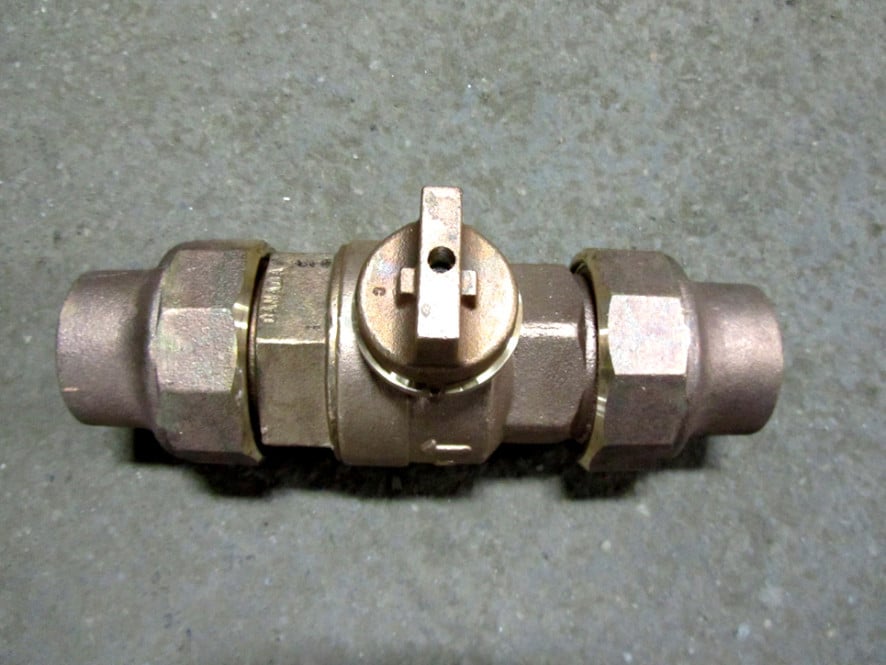

Sidewalk valves generally are known as curb valves and are made in two distinct styles. A curb valve with a notched top only needs 1/4 of a turn to open or close it fully, just like regular ball type water main valves. Like all valves it should never be jerked or operated with excessive force, even pressure must always be applied.

Did you know that in NYC all fire mains and water lines larger than 2″ require a curb valve with an operating box? Any such main that does not have a curb valve is subject to a violation from either the Fire Department or the DEP.

A curb valve with an operating nut on top needs a number of turns to either open or close the valve. The number of turns depends on the size of the valve, the larger the valve the more turns required. Water main valves of this type should never be forced closed – if they do not close fully the first time they should be gently worked back-and-forth.

By working gate type water main valves back and forth with water running through them any sediment or debris can be flushed out. This should then allow the valve to close fully.

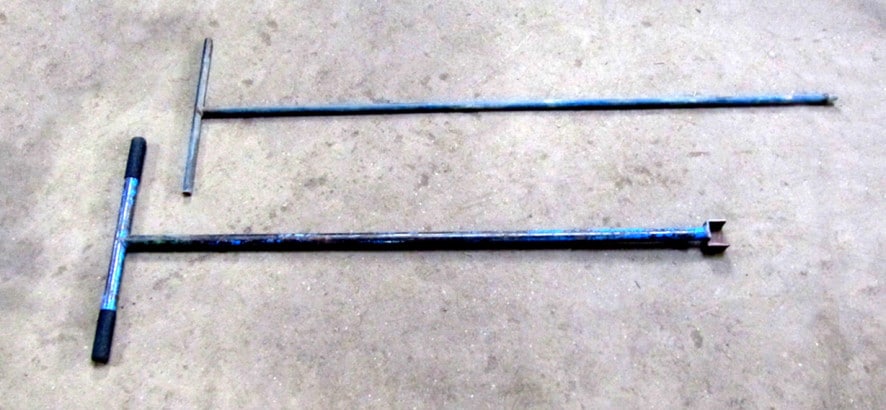

Breaking a curb valve, or any valve for that matter, due to mishandling it will result in very costly water line repairs. Not to mention an extreme inconvenience to the occupants of the property. Each type of curb valve needs a special key designed specifically for that style of valve, either a square headed key or a notched key.

Sometimes even what may seem like a simple plumbing task is best handled by a licensed professional plumber. Having the expertise and correct tools can stop what seems like a simple plumbing situation from getting very complicated before you know it.

Trust a licensed, bonded, and insured NYC Master Plumber to do it right the first time.