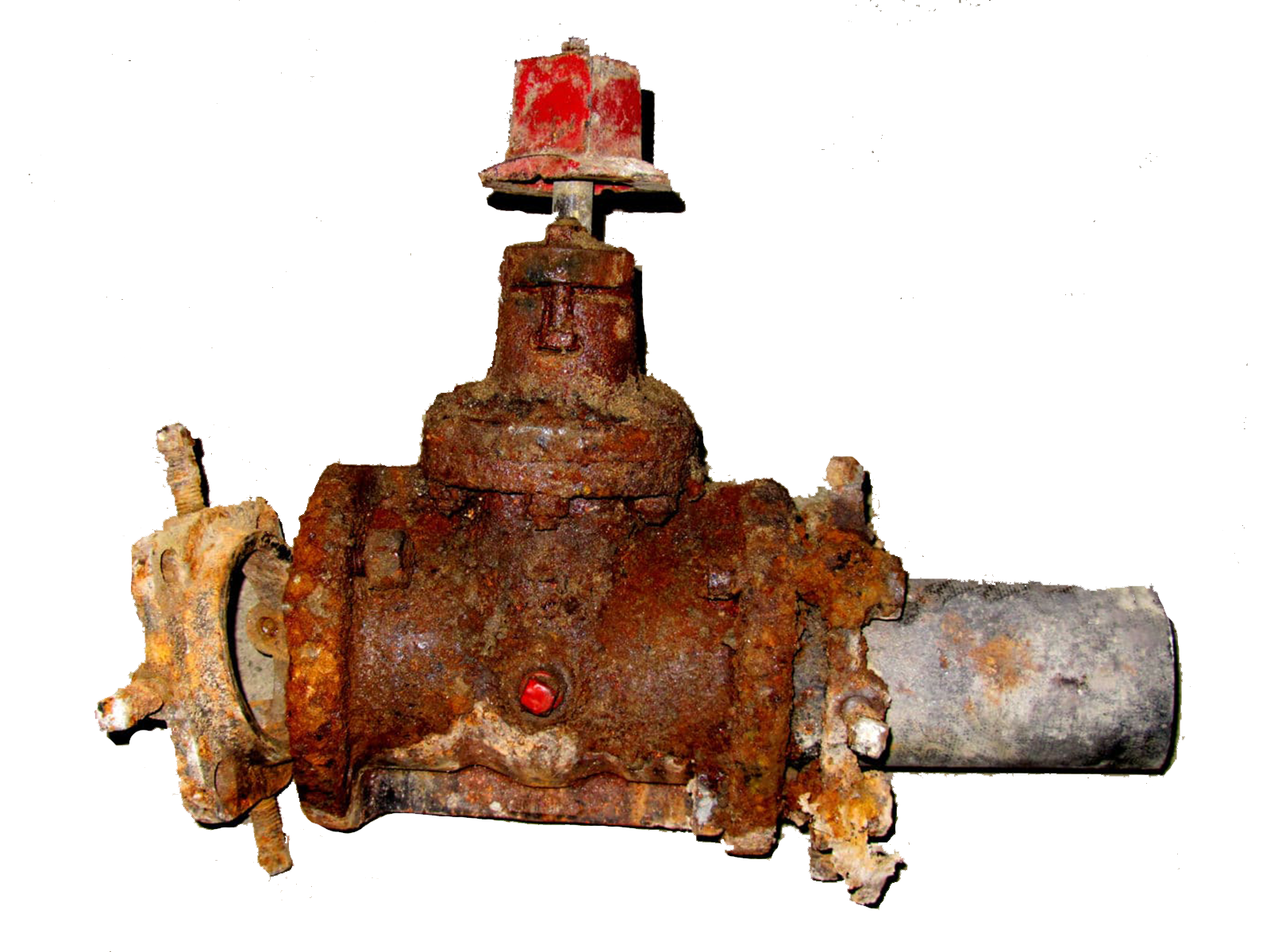

A gate valve for your property usually has to be closed if plumbing repairs or maintenance are needed inside your building. In some instances, particularly if the main control valve is a gate-type valve, the valve may not close completely. In many cases, a gate valve repair may be needed. But many times there are other remedies also available.

A gate valve that will not close completely is not unusual

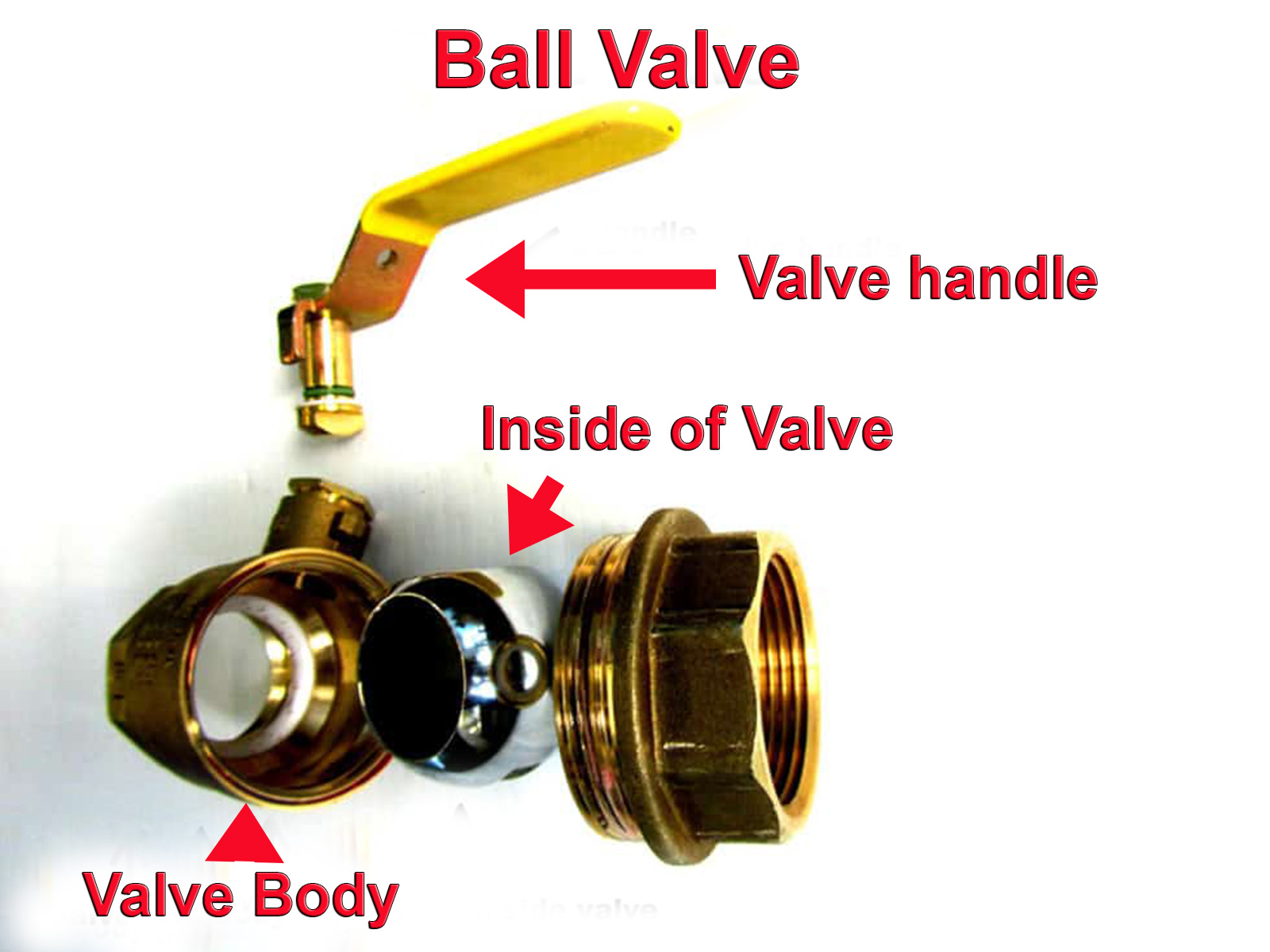

A gate valve not closing completely is fairly typical. That is primarily due to sediment that has built up inside the body of the valve. The sediment becomes lodged between the gate that lowers, and the inside of the valve body itself. Ball-type valves do not suffer from this problem, as they operate on a different principle than a gate that raises, and then lowers inside of the valve body.

Your typical reaction when a gate valve will not close fully is to exert additional force on the handle. Using force to close a valve is the wrong response. Brute force can cause permanent damage to the valve, and a loss of water supply to your building. If sediment or mineral deposits are preventing the gate valve from closing fully, there are more sensible gate valve repair suggestions to consider, other than brute force.

The first step if a gate valve will not close completely

If sediment or mineral deposits are preventing a gate from closing completely, an attempt should be made to flush out the inside of the valve. The proper way to do this is to open a faucet on a sink inside the house, so there is a flow of water. Then gently and repeatedly open and close the valve.

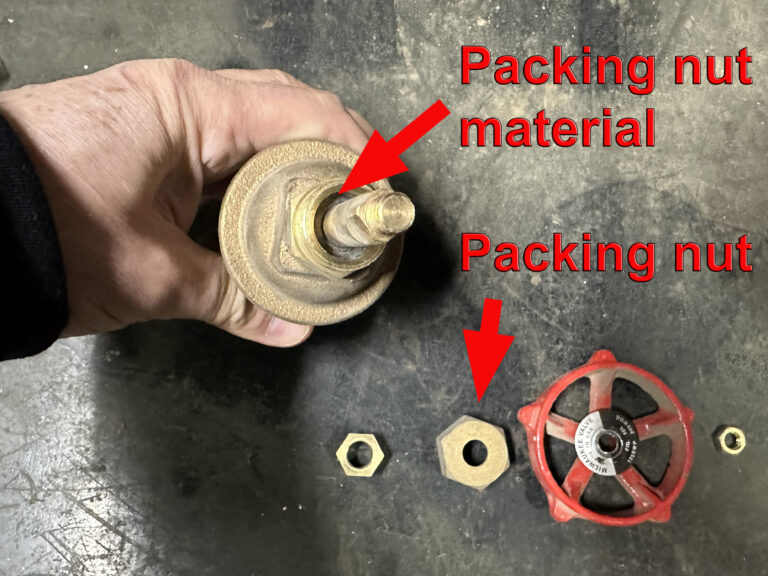

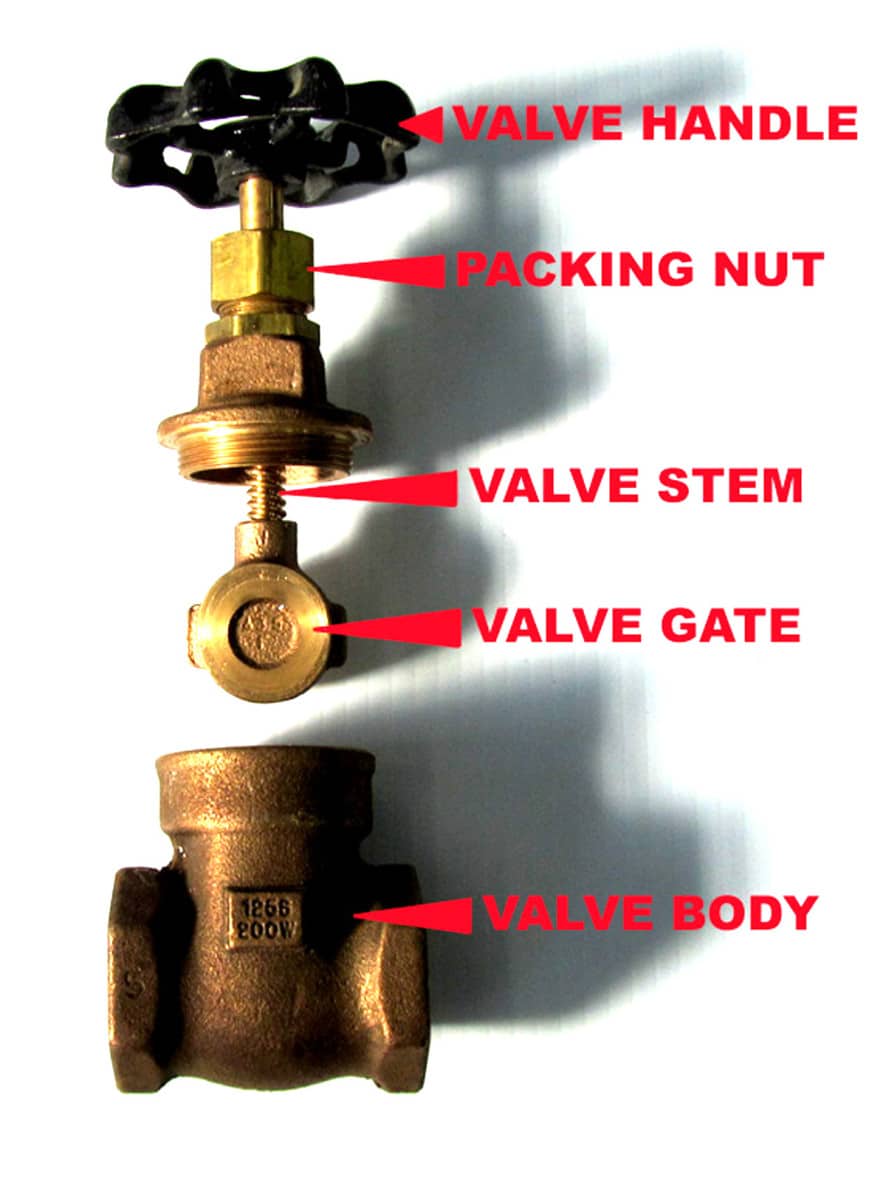

If the handle of the valve does not turn freely, then loosen the packing nut just above the valve body and around the stem of the valve. Loosening it just one turn should be fine – just remember to tighten it back up when you are done. Every time you lower the gate some sediment will break free and be flushed away by the water flow. There is no harm or danger in how many times you do this as long as no excessive force is used.

Routinely opening and closing a gate valve helps it to last longer than if it is left frozen in place for long periods of time. This is called exercising the valve and can help avoid ever needing a gate valve repair. Experienced building managers make this chore a part of their standard maintenance duties. Water valves should be exercised to prevent them from “freezing in place” or accumulating sediment inside the valve body.

What if the valve stops almost all of the water flow?

Sometimes a little water will continue to flow after a gate valve is closed as fully as possible. In some cases, the plumbing repairs inside the property can be performed with that little bit of water flowing through the system. But there is another option as well. If there is a slight flow of water the easiest solution is to jump the valve.

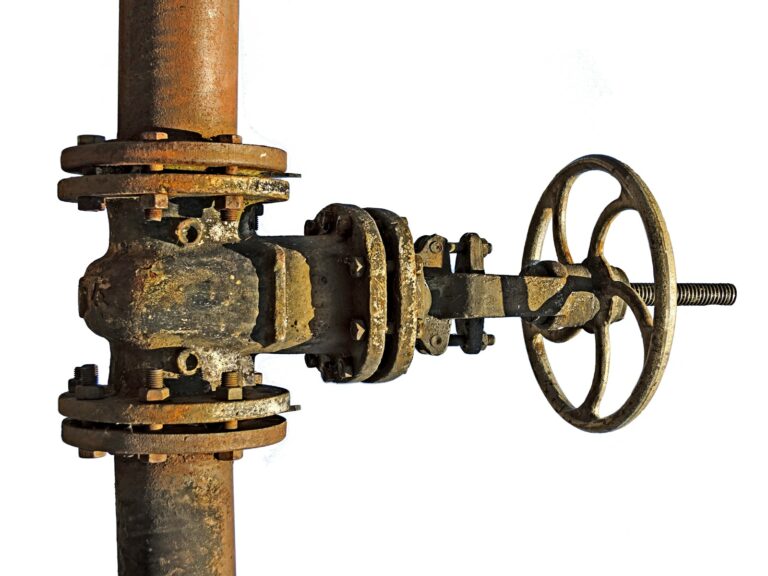

Jumping a valve simply means to leave the defective valve in place, and simply install a brand new valve after it. This method completely avoids trying to do a gate valve repair on the old valve. If legal for your area, and your type of water service line, the preferred valve to use is a ball-type valve. A full port ball valve allows for full flow of water, is rated higher than most gate valves, is longer lasting, and is not prone to break.

If you choose to install a second main control valve it is a good idea to remove the handle on the original valve or label it. This acts as a reminder, so it is not used again in the future. The last thing you would want to do is to use an old defective valve in the future and have it break in the closed position.

Gate valve repair: When a valve breaks in the closed position

In most cases, if a gate valve breaks in the closed position, gate valve repair work has to be done. Sometimes a curb stop valve will be located in the sidewalk area. This would enable you to close the curb valve and the water by using a curb box key. A curb box key is a specialty water main tool and comes in a variety of styles. Once the water is closed, you can then remove the broken valve with little trouble.

If there is very little room to work inside the basement where the valve is located, and there is no curb valve, the roadway may have to be opened to close the tap connection itself. Opening the roadway can be fairly costly and will involve securing DOT permits.

Changing out a main control valve under pressure can be a very tricky proposition, and should be considered the most potentially dangerous gate valve repair. Removing a valve under water pressure can sometimes be done by highly skilled plumbers, but never when live electric services are nearby. When a gate valve repair is needed, there are many nuances to getting the job done correctly. One should never risk an injury or property damage just to save a few dollars.

Can you rebuild a gate valve?

For most homeowners, the low actual cost of a new gate valve will not warrant trying to rebuild it. In some cases, due to the size of the gate valve, or the sensitive location, rebuilding a gate valve may be a viable option. In those rare cases, this article on how to rebuild a gate valve can come in handy.

Sharing a “Trick Of The Trade” when a gate valve breaks

If a gate breaks in the closed position, there may seem to be no way to raise it back up to restore water service. However, there is a trick in the plumbing trade. By drilling a small hole near the bottom of the valve body in line with the gate, a nail or some other sharp object can be pushed in to force up the gate of the valve. Water will leak out while this is being done but it will be a manageable amount.

After the valve gate is pushed up, simply insert a like-sized sheet metal screw into the hole to stop the water. Please note that while this will restore the water supply to the building it is a temporary gate valve repair fix. The gate valve will still have to be replaced to make a permanent repair and have a trustworthy valve to close the water in the future.

As in most cases, it is strongly suggested that a Licensed Master Plumber be contacted when a plumbing repair is required.